Penetrant Testing

NDT course on Penetrant Testing

Computer Based Training Course on "LIQUID PENETRANT TESTING"

|

|

CONTENTS: Liquid Penetrant Testing(see |

||

|

|

||

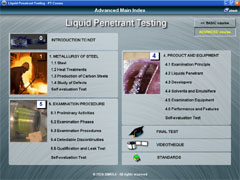

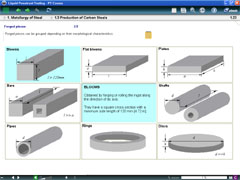

1. METALLURGY OF STEEL

|

|

||

2. METHOD PRINCIPLES

|

|

||

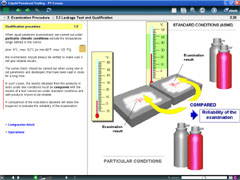

3. EXAMINATION PROCEDURE

|

|

||

4. PRODUCTS AND EQUIPMENT

|

|

||

5. EXAMINATION PROCEDURE

|

|

||

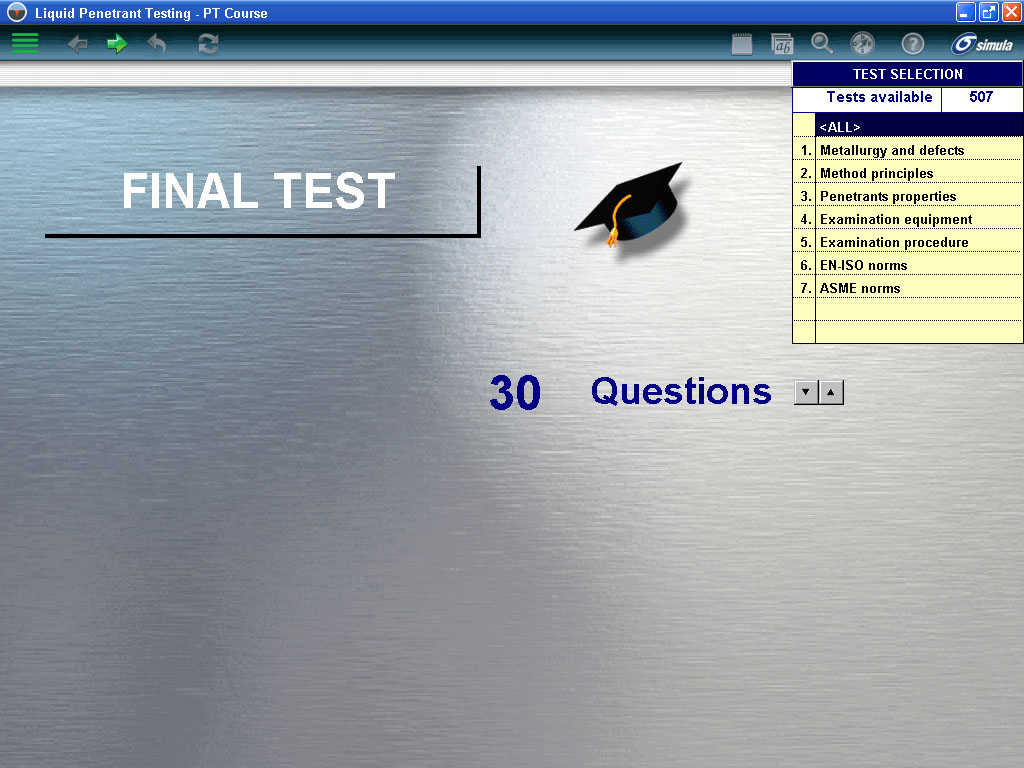

FINAL TEST

|

|

||

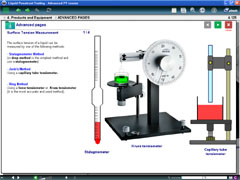

ADVANCED PAGES

|

|

||

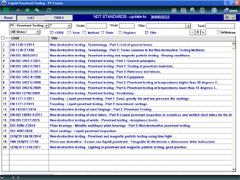

NORMS

|

|

||